Product name:Chlorinated polyethylene CPE

Product overview: Chlorinated polyethylene (CPE) is a new thermoplastic elastomer material made of polyethylene as raw material by chlorination. The product is white, non-toxic and tasteless. Its special molecular structure and aggregation form determine that CPE has a series of excellent physical and chemical properties, and has been widely used in the field of plastics and rubber. Because of its excellent comprehensive performance and ideal cost performance, it is favored by users.

- Technology and features

- Product index

- Product application

- Product packaging

Technical support

Yaxing has a chlor-alkali production plant with capacity of 120,000t/mt, which ensures chlorine supply for CPE production. The company has been since many years in strategic cooperation with Honam Petrochemical Corporation, one of the biggest PE producers in South Korea. And Yaxing also has good strategic relationships with other domestic and foreign PE producers. This raw material supply guarantee is the base for Yaxing’s continuous development of new grades of CPE for the market’s new demand.

or multi-loop cascade control, which makes the real process move on precisely following the predesigned programmes. For example, the vibration of the

reaction temperature, one of the key control parameters, can be controlled within ±0.1℃ precision. This advanced control technology serves as the base

for all of our CPE standards to fully reach their original design.

Advanced Equipment

enamel reactors equipped with agitating and frequency conversion system make the reaction go stably and orderly. The plate filters and centrifuges made

of special materials effectively realize continuous operation of deacidification, water-washing and centrifuging.

The anti-static airflow drying system and milling system ensure production of CPE with uniform quality.

Quality assurance

◆Yaxin has obtained ISO9001 quality management system certification, ISO14001 environmental management system certification, ISO10012 measurement management system certification, ISO45001 occupational health and safety management system certification ISO50001 energy management system certification.

Unique Characteristics of Yaxiing WEIPREN®CPE

◆Unique Production Technologies and Equipment

The globally biggest 60m3 enamel chlorination reactors with stable running.

Using the most advanced control system globally

Many testing and piloting devices for high polymer materials imported from foreign countries.

The products have many series with different performances and are widely used in many applications.

High concentration HCl as the byproduct is fully sold as formal product. The production method is clean and environmentally friendly.

Product index

WEIPREN®CPE is divided into WEIPREN®RESIN (resin) and WEIPREN®CM (synthetic rubber) two categories according to its end use. WEIPREN®RESIN is mainly used for plastic modification, while WEIPREN®CM is mainly used for special rubber. These two categories of products are divided into multiple grades according to different technical indicators.

1. Properties of WEIPREN®RESIN

◆Superior flexibility and impact resistance

◆Superior filling capacity

◆Good low temperature performance and weatherability

◆Superior flame retardancy

◆Superior compatibility with polymers such as PVC, PE and ABS

◆Superior chemicals resistance

◆Superior dispersibility and processibility

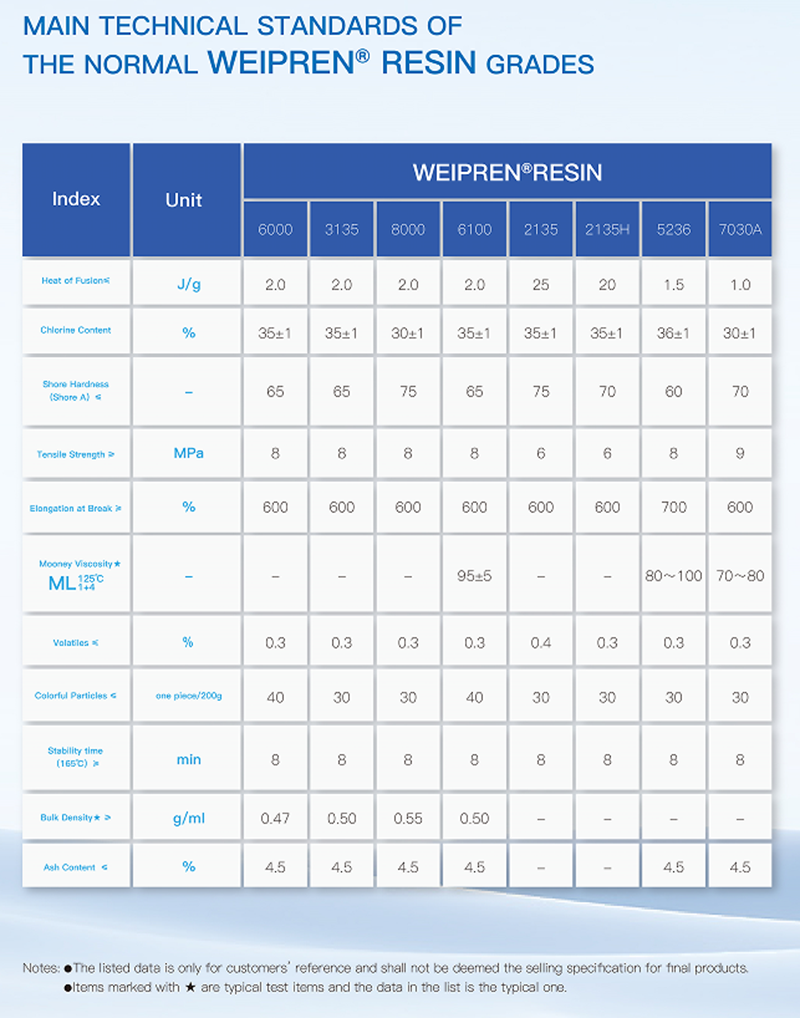

WEIPREN®RESIN Main technical specifications of conventional grades

By setting different parameters, Yaxin can produce a variety of market demand WEIPREN®RESIN products, in addition to long-term stability to provide conventional brand WEIPREN®RESIN for users to choose, but also according to the special requirements of users, to design a proprietary brand to meet the personalized requirements of users.

2. Properties of of WEIPREN®CM (Rubber)

◆ Superior mechanical performances

◆ Good low temperature performances

◆ Superior heat aging performances, weatherability and chemicals resistance

◆Superior flex-resistance

◆ Good flame retardancy and machine oil resistance

◆ Long storage time

◆ Ideal cost effectiveness

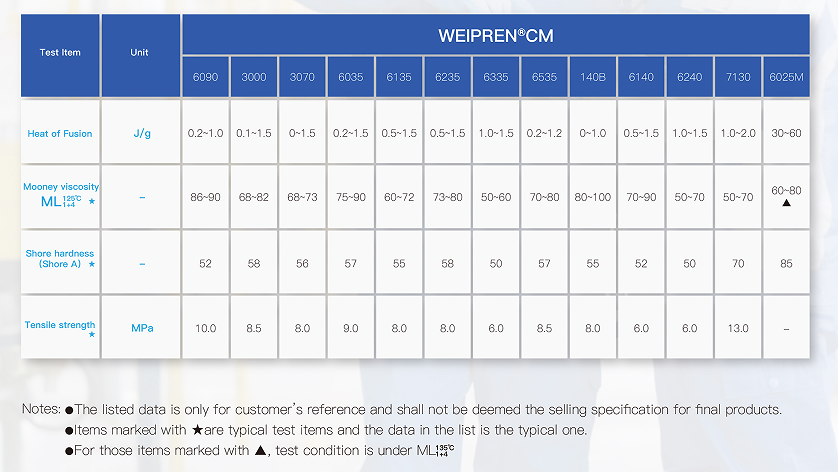

Main Technical Specifications of the Normal WEIPREN®CM Grades

By adopting different PE materials and setting up different process control parameters and product specifications, more WEIPREN®CM grades can be produced. Obviously different performances can fulfill special requirements in different applications. Therefore, customers can select normal grades or grades of special requirement based on its processing conditions and technical requirements of its final products.

1. Application of WEIPREN®RESIN

◆ PVC Modification

WEIPREN®RESIN, as an excellent and cost-effective impact modifier, is widely used in the production of hard plastic products such as hard plastic profiles, pipes, pipe fittings, panels and other hard plastic products as well as building exterior wall laminate, building anticorrosion, moisture proof thin wall panels. WEIPREN®RESIN can promote PVC plasticization, improve the processing performance, and can greatly improve the impact strength of the product, significantly improve its low temperature resistance and weather resistance.

◆Flame Retardant ABS

WEIPREN®RESIN itself is a flame retardant material with excellent compatibility with flame retardants. In the formulation of flame retardant ABS, the amount of flame retardants can be reduced, and the filling performance can be improved without reducing the impact resistance of flame retardant products. The number of copies to be added depends on the specific equipment process and customer's specific index requirements (recommended number: 5 to 15 copies). Weipren2135 developed by Yaxing has good thermal stability, moderate fluidity, high filling and good compatibility with ABS, which is suitable for application in the field of flame retardant ABS.

◆ Magnetic material

WEIPREN®RESIN 7030 has a very high filling property for ferrite magnetic powder, and the magnetic material made of it has a strong magnetic attraction, and the rubber products have good low temperature flexibility and extensibility. It is widely used as refrigerator sealing strip, magnetic plate, magnetic strip and other products. The heat resistance of WEIPREN®RESIN can also be used to make magnetic components for electromechanical products.

◆ Soft products

As an excellent elastomer, WEIPREN®RESIN can be directly used to produce soft products. The plasticizer can be added without or less in the formula, and the soft products produced have particularly good weather resistance and long service life. Avoid the traditional PVC soft products due to a large number of plasticizer migration and eventually lead to the deterioration of the physical and chemical properties of the product, greatly extending the service life of the soft products. It is widely used in waterproof coil, shoe material, plastic wire, sealing strip, tarpaulin, canopy and other soft products.

◆ Modifying PE,PP and other General Plastics

In the structure of WEIPREN®RESIN, similar molecular segments determine good compatibility with general plastics such as PE. After filling, it can effectively reduce the hardness of plastic products, improve the weather resistance, ozone aging resistance, and improve the flame retardant.

◆ Modifying EVA,TPUand other Plastics

|  |  |  |

2. Application of WEIPREN®CM

◆ Wires and Cables

WEIPREN®CM has good mechanical properties, good electrical insulation properties, excellent processing properties, and is widely used in the field of wire and cable, including: A variety of oil-resistant parallel flexible wire (such as HPN type wire) insulation layer, consumer electrical appliances (such as electric heaters, cookware, air conditioners, refrigerators) with flexible wire or flexible cable sheath, a variety of light, medium and heavy cable sheath, mining cable, Marine cable, locomotive cable sheath, a variety of power/instrument/control cable insulation layer or sheath. In the wire and cable industry, WEIPREN®CM has become the preferred raw material for users due to its good cost performance and long-term storage of its vulcanizates at room temperature.

◆ Insulation Performance

|  |

|  |

The chlorination process of WEIPREN®CM is carried out in the enamel reactor, there is no infiltration of metal ions, the post-treatment does not require alkali washing, and there is no attachment of conductive ions, so it has good insulation performance. The volume resistance of WEIPREN®CM raw film can reach 1013~1014Ω•cm. The improved brands Weipren7130 and Weipren6535 produced by Yaxing have better insulation properties.

◆ Auto hose and industrial hose

Because WEIPREN®CM has good heat, oil, chemical, ozone and flexure resistance, and high fixed elongation strength, WEIPREN®CM is the ideal raw material choice for the automotive industry. WEIPREN®CM in the automotive industry applications include: automotive transmission oil pipe, brake pipe, power steering pipe, engine intake pipe, exhaust pipe, etc., can also be used for automotive engine oil pipe, air conditioning pipe and other hose outer rubber. WEIPREN®CM also has a broad market in industrial oil, chemical and mining hose.

◆Various Types of Specialized Rubber Products.

Because WEIPREN®CM has excellent heat resistance, oil resistance, chemical resistance and aging resistance, it can be used to make special rubber products such as engineering rubber, sealing rings, gaskets, linings, and can also be used to make special rubber materials such as tape.

◆ Use Together with Other Rubbers.

WEIPREN®CM is used with other rubbers such as EPDM, NBR, CSM, CR, IIR, SBR, etc., which can reduce the cost and make up for some of the shortcomings of other rubbers.

|  |  |  |  |

| 1.5t pallet packing | 25kg PE bag packing | 25kg EVA bag packing | 25kg PP bag packing |

Packaging

Yaxing has various types of packages to meet different requirements from the market. The forms of packages are:

25kg PP bags,

25kg PE bags,

500kg/600kg/750kg/900kg/1000kg big bags,

25kg low melting point EVA bags specially made for rubber customers.

Moreover,as per customers’ mechanized loading and unloading requests, fumigation or non-fumigation pallets are used for loading 1-1.5 tons of product.

wechat

wechat

Please scan QR code for mobile browsing

Please scan QR code for mobile browsing